If your business ships freight using less-than-truckload (LTL) services, it is vitally important to understand freight classification. Originally created for the railroad freight industry, and later adopted by the LTL industry, freight classification was established to categorize goods and standardize shipping prices.

Identifying the correct LTL freight class can be a tall order, and incorrect classifications can be costly to your bottom line. By understanding the basics behind freight classification, you can avoid pricey charges that affect the overall cost of your company’s freight shipments.

What is Freight Classification?

Freight classification, or “freight class,” is a unit of measurement defined by the National Motor Freight Traffic Association (NMFTA) that standardizes and simplifies elements of the shipping process.

As we know, products come in all shapes, sizes, and weights, and those variables can change the way a product is packed to be shipped, and how expensive it will be to transport. Outlined by NMFTA, every commodity can be identified by a National Motor Freight Classification (NMFC) code that describes the characteristics of the product being shipped. Each NMFC code is unique to the item it describes, including the materials it is made of and its purpose of use.

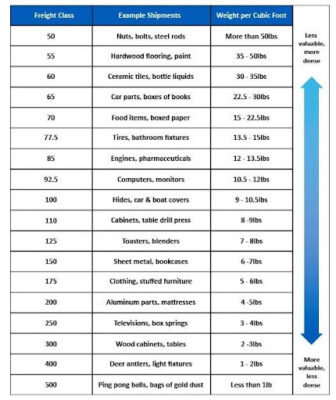

Using NMFC, freight is grouped into one of 18 classes, ranging from a low class of 50 to a high class of 500. Low freight classes generally translate into lower freight costs, while goods that ship at a higher freight class are the most expensive to ship. These classes are an industry-standard set by the NMFC tariff, which contains rules, descriptions, and ratings for all commodities and governs the associated price offered by individual carriers.

How is Freight Class Determined?

There are four unique components that determine the freight class of a shipment: density, handling, stow-ability, and liability. These elements combined inform a carrier about the potential risks and costs of shipping a product. In short, the less risk the carrier has, the less expensive it will be to ship.

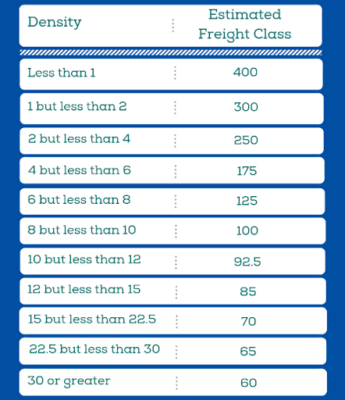

Density is defined as the pounds per cubic foot of your shipment and is calculated by dividing the total cubic feet by the total weight in pounds. In general, the denser a product, the less expensive it will be to ship. One reason for this is that unlike full truckload carriers, who typically prefer lighter loads that require less fuel to haul, LTL carriers are looking to max out the capacity of their trailers.

Consider this example of a truckload of feathers versus a truckload of bricks. If a trailer can hold 26 pallets, the pallets of bricks will come closer to or exceed the weight capacity for the trailer. 26 pallets of feathers, however, will be much lighter than the total weight capacity the trailer can handle.

When shipping LTL, a carrier is looking to max out all capacities to maximize efficiency, so while the truckload of feathers may take up all the physical space of the trailer, it will not come close to reaching the maximum weight the trailer can hold. For this reason, density is a huge determining factor in freight classification.

Handling refers to the ease or difficulty of moving freight from one terminal to another until it reaches its end destination. Because LTL networks are expansive, a shipment may land at multiple service terminals throughout the lifespan of the shipment before arriving at the consignee. If an item is fragile and at higher risk of being broken in transit, the freight cost will increase to cover the likelihood of damages occurring.

Handling also includes how freight is packaged and how easily it can be loaded and unloaded from a trailer. Freight that is palletized on standard 48×40 inch pallets that can be moved easily with a pallet jack or forklift will have a lower freight class, while items such as large crates or awkwardly shaped packages are harder to maneuver and will be classed higher.

Stow-ability takes look at how difficult freight will be to store and ship compared with other nearby cargo. For this, think size and shape of the commodity. Along similar lines as handling, items that are heavy, fragile, awkwardly shaped, or hazardous are more difficult to load, ship or store throughout the shipment’s lifespan and those difficulties can lead to increases in freight class.

Liability encompasses the likelihood that freight may be damaged or stolen in transit, or cause damage to nearby freight. Hazardous freight, or freight that could combust or explode, for instance, would have a higher liability and result in a higher freight class. The same can be said for items that are fragile and easily broken in transit.

While density, handling, stow-ability, and liability are the major determinants of freight class, it is important to note that some commodities are fixed class items that have a permanent freight class, regardless of size and weight. Most HAZMAT items, for example, have a fixed freight class. Refer to the NMFC code guidelines for the specific commodity to determine whether the freight class must be calculated, or if it is fixed.

Finding the Correct Freight Class

To determine the correct freight class of a shipment, start by identifying the corresponding NMFC code from the NMFC database. A guide to the database can be found on the NMFTA website using the following link: NMFC.

If the NMFC code for the product you are shipping is fixed, then there will only be one freight class to use for the shipment. If the class is density-based, then the freight class will be indexed for that code based on the density of the freight. Follow the instructions below to determine the density of your freight:

- Calculate the length, width, and height of your freight in inches. Round up to the nearest inch.

- Multiply the three measurements together (length x width x height) to calculate the size of your freight in cubic inches.

- Convert the calculation to cubic feet by dividing the number by 1,728 (the number of cubic inches in a cubic foot).

- Divide the weight of the freight (in pounds) by the total cubic feet. The resulting number is the density of your freight.

Once the density of the shipment is determined, refer to the freight class index specific to the NMFC code of your product and determine which class corresponds to the density you calculated. That will be the freight class of your shipment.

What Happens If You Ship Using The Wrong Freight Class?

The correct freight class and NMFC code must be included on the BOL for all LTL shipments. If the freight class is incorrect, potential issues such as the following may occur:

- Freight may be subject to re-classification and subsequent fees

- Freight may not fit within the carrier’s weight, storage or equipment capacities leading to additional fines

- Freight may be mishandled resulting in damages and financial loss

- Freight classification disputes are complex and time consuming and usually result in the favor of the carrier

In Conclusion

Determining the correct freight class can be tricky, and if done wrong can result in costly freight charges. Contact 5 Logistics with your freight classification questions and let us help drive you toward worry-free shipping. Need an LTL quote? Call us today!

References

Freight Class Calculator: How to Determine Freight Class | FedEx

A Guide to Understanding Freight Class

How to determine freight class: A comprehensive guide

Understanding Freight Classifications – Trans Audit

What Is Freight Class & How Do You Determine Yours?.

The Importance of Freight Class When Shipping Goods

5 Logistics

5 Logistics