What is a Delivery Area Surcharge on My Shipping Bill?

What is a Delivery Area Surcharge? Most shipping carriers charge additional fees called assessorial or surcharges to account for packages that have additional costs to handle. One of the most common of these surcharges is the Delivery Area Surcharge, often ...

Unveiling GS1: Revolutionizing Retail Through Standardization

In the fast-paced world of e-commerce, where efficiency and accuracy are paramount, understanding and implementing standardized business practices is key. One such standard that plays a crucial role in the retail industry is GS1, or Global Standards 1. In this ...

Denver Fulfillment Center: 5 Reasons for Choosing the Mile-High City for your eCommerce Fulfillment

5 Logistics’, a Denver fulfillment center, main headquarters is located just 8 miles outside of the vibrant Denver-Metro area – a city that boasts breathtaking mountain views, a lively music scene, and a culinary landscape sure to satisfy every palate ...

Route Insurance: A Brief Overview of Preventing Inevitable Shipping Losses

Let’s talk about Route Insurance – what is it and why it matters. Online shopping has become a part of our daily routine. With the convenience of shopping from the comfort of your own home, it’s no surprise that the ...

Protecting Your eCommerce Business from Fraudulent Transactions Using Fraud Prevention Apps & Basic Protocols

As eCommerce business continues to grow, so does the frequency of fraudulent transactions. You can work to protect your business by using fraud prevention apps and basic protocols. Fraudulent transactions can cause significant losses for eCommerce businesses, making it essential ...

Boost Your eCommerce Marketing Communication Flows with Klaviyo

Are you struggling to connect with your customers and drive more sales on your eCommerce store? Have you considered using an email or SMS marketing automation tool to streamline your eCommerce marketing communication flows, but don’t know where to start? ...

FedEx Picture Proof of Delivery

The much-anticipated announcement was made on July 22nd, 2022 — FedEx picture proof of deliveries on recipients’ doorsteps will soon begin nationwide. The new service is called Picture Perfect Delivery and customers will not be required to sign up for ...

Faire Marketplace: A Great Add-On for DTC Businesses

Faire is an online wholesale marketplace based in San Francisco that was created in 2017 with the mission of helping independent entrepreneurs realize their dreams and be able to successfully compete with larger competitors. Faire connects retailers with makers (sellers) ...

Understanding Customs Duties and Taxes – International Shipments

When sending international shipments, it’s important to consider the effects that customs Duties & Taxes will have on the total landed cost of your shipments. Depending on the commodity being shipped and the destination it’s headed to, clearance charges could ...

Recharge – The Subscription Management App of Choice for eCommerce

In 2014, an entrepreneur named Oisin O’Connor launched Recharge which offers a subscription management service for shopping cart marketplaces and gives eCommerce merchants the ability to launch and scale subscription programs. Recharge not only makes managing customer subscriptions easy, it ...

Shopify Monthly Subscription Plans

Shopify is a subscription-based eCommerce platform that helps businesses of all sizes launch online storefronts and immediately begin selling their goods to customers all over the world. Shopify wisely realized that the value of their platform stemmed from the number ...

Understanding the Importance of a Bill of Lading (BOL)

Whether you’re shipping a full truckload (FTL) or less-than-truckload (LTL) freight shipment, it is vitally important that the shipment is accompanied by a Bill of Lading. Also known in the industry as a BOL, this is a legal document outlining ...

Shopify – The Powerful eCommerce Shopping Cart Platform

Shopify was founded in 2006 by Toby Lutke because he could not find a simple set of software tools to build his own eCommerce website. Toby lives in Canada and was looking to create a niche site to sell snowboards ...

Understanding and Explaining Fuel Surcharges

Fuel surcharges (FSCs) are a pivotal component in the transportation and logistics industry. They serve as a financial buffer for carriers against the unpredictable and often volatile fluctuations in fuel prices. These extra charges can greatly affect the shipping cost ...

3PL Tips for Amazon FBA-Prep

Amazon is the undisputed juggernaut in the world of online commerce and many clients ask us about our Amazon FBA-prep service. Their dominance in the space does not mean that your company should rely on Amazon for 100% of your ...

Understanding LTL Freight Classification in 2022

If your business ships freight using less-than-truckload (LTL) services, it is vitally important to understand freight classification. Originally created for the railroad freight industry, and later adopted by the LTL industry, freight classification was established to categorize goods and standardize ...

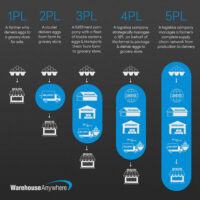

What Are 1PL’s, 2PL’s, 3PL’s, 4PL’s, & 5PL’s?

The world of logistics is a dynamic and rapidly evolving environment. As a nation of on-demand consumers, we are all greatly dependent upon the various companies that make up the logistics spiderweb that is ingrained in the fabric of our ...

Should Your Business be Using TikTok for Marketing in 2022?

If your business sells products on an eCommerce platform, you are probably no stranger to the world of direct response online marketing. Successful TikTok marketing campaigns can be a driving force for sales, and it’s no secret that social media ...

Shipping Costs 101: Dimensional Weight & Delivery Area Surcharges

Shipping costs should be simple right? You place your packed box on the scale, enter the customer’s address, and get a price from the shipping software. The package is then tendered to the carrier and a happy customer awaits the ...

Shipping Container Logjam Expected to Affect Q4-2021 eCommerce Traditional Sales Patterns

If you’ve been listening to any business news outlet lately, you’ve no doubt heard about the countless supply chain issues that continue to persist around the world. We’ve all gotten used to the new “COVID-related” delays in our everyday lives ...

How will the 10-Year Plan for USPS® Impact eCommerce?

On March 23 of 2021, the venerable United States Postal Service, under the direction of their new Postmaster Louis DeJoy, announced a 10-year Strategic Plan to stem it’s annual operating losses and achieve financial sustainability while delivering service excellence. Excellence and USPS® are ...

A Guide to Fulfillment Warehousing

In the fast-paced realm of e-commerce, the role of fulfillment warehousing is pivotal in determining the success and efficiency of your business operations. This guide aims to deepen your understanding of fulfillment warehousing, highlighting why it’s integral to e-commerce and ...

What is a 3PL, Anyways?

3PL is a term that gets mentioned a lot in the world of logistics. Most users of a 3PL don’t really understand exactly what it means, just that “they have a warehouse”. So, what is a 3PL anyway? 3PL stands ...

When Should I Outsource to a Fulfillment Center (3PL)?

In the dynamic world of e-commerce, the decision to outsource to a fulfillment center, its logistics, and order fulfillment to a third-party logistics (3PL) provider, like a fulfillment center, is a strategic one that can significantly influence the trajectory of ...

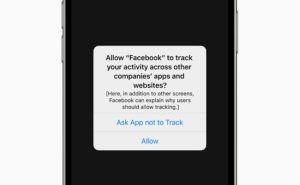

Apple’s ATT Deployment

Apple’s ATT Deployment and The Impact on DTC Fulfillment Apple’s hotly contested App Tracking Transparency (ATT) policy started rolling out in late April with the release of iOS 14.5. The repercussions for small businesses are now becoming a reality, especially those ...

5 Logistics

5 Logistics